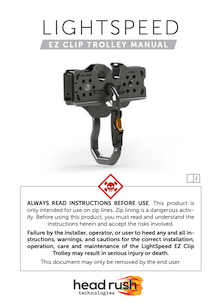

LightSpeed EZ Clip Trolley

As low as

$229.00

Ez Clip Trolleys are currently on backorder

The LightSpeed EZ Clip Trolley is durable and lightweight. With easy, one-handed installation, the LightSpeed EZ Clip Trolley the perfect combination of performance and convenience.

Specifications

- Dimensions: 145 mm (5.7 in)

- Weight: 507 grams (1.1 lb)

- Rated Working Capacity: 15-150 kg (33-330 lbs)

- Cable Line Diameter: 9.5 mm ≤ ø ≤ 13 mm (3/8 in ≤ ø ≤ 1/2 in)

Features

- Made of high-strength, tempered aluminum alloy

- The patent-pending trigger-activated installation provides ease of use and maximizes throughput

- Four self-contained, ABEC-rated bearings make these the longest lasting compact trolleys

- Rated for speeds up to 121kph (75mph) and impact speeds of 72kph (45mph)

- The integrated impact surface is designed for durability in braking

- The patent-pending design pivots with the rider to keep both sheaves on the cable during braking

- The curve-over design of the backup carabiner slot keeps the backup carabiner in place throughout braking (reducing wear on your line)

- Optional catch accessory integrates with zipSTOP Brake Trolley to aid in rider retrieval.

You may also be interested in

-

![zip line handle for the LightSpeed EZ Clip Zip Line Trolley with plastic handles and metal base]() EZ Clip Handlebar$119.00

EZ Clip Handlebar$119.00